Roll Wear Signs to Look For

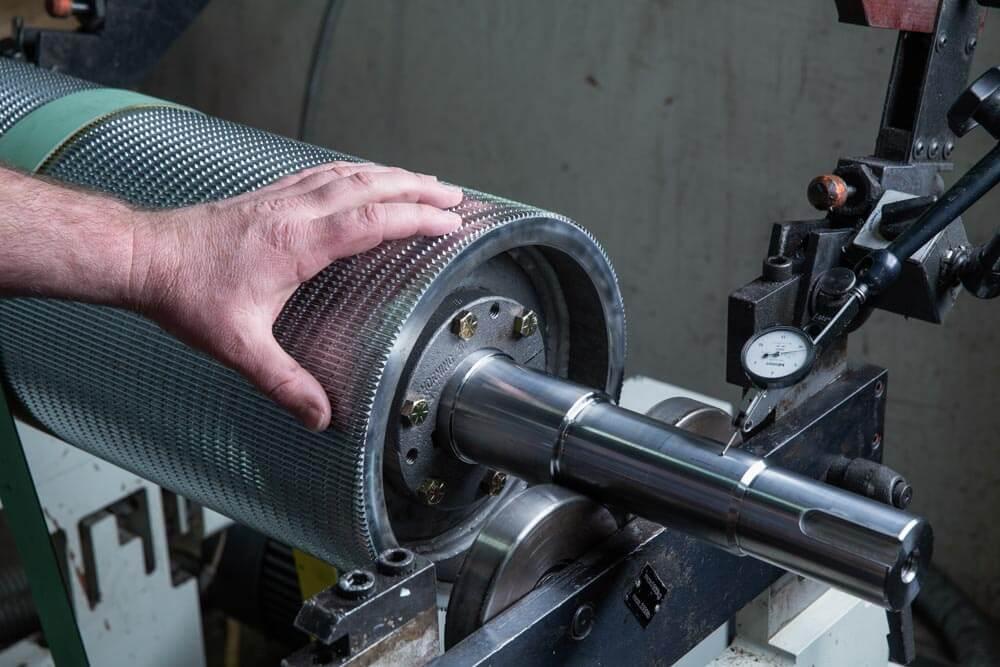

When you bought your rolls from Horning, you invested in products made from premium metal that were heat-treated to increase wear resistance. If you upgraded to our chrome-plated models, you had the confidence that your investment would last even longer.

Getting the longest life possible out of your investment is the goal. But in the rugged world of forage processing, even the best products will eventually wear down. Friction, foreign objects, and dirt all take their toll on equipment parts. Since you know that your rolls will eventually wear out, how do you know when it's time to replace them?

Here are some things to look for:

Reduction in processing quality (lower KP score)

This is probably the clearest indicator of worn-out rolls. An ideal KP score is 70 and above, while below 60 is poor. If you are seeing any whole kernels (or even large pieces of kernels) in your silage and your KP score is trending downward (in spite of proper adjustments), your rolls may be nearing the end of their life.

A weak or broken spring, damaged washers, or incorrect speed differential can cause poor-quality processing.

Plugging

Depending on the material that you are processing, plugging can happen even with newer rolls. Some weeds, especially dead foxtail (or similar grasses) on a wet morning, tend to create these problems. But if you are having any plugging issues, the problem will likely get progressively worse till the rolls are replaced.

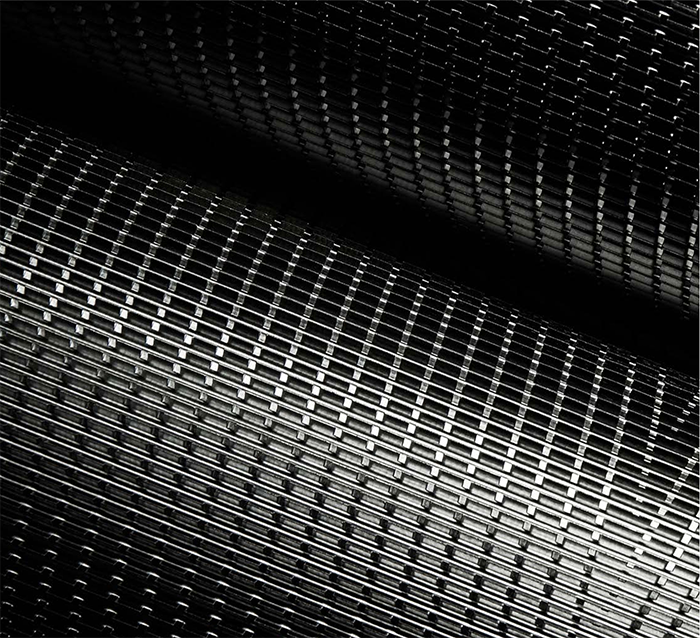

Inconsistent diameter

When your rolls are new, they will have a consistent diameter. But as they wear, you may start to notice that the gaps at the ends of the rolls are no longer as close as the centers.

As you see your KP scores dropping, you may try to bring the rolls closer together. But because the worn rolls are not consistently parallel, kernels will likely be getting past the wider gaps.

If you find a lot of areas on the rolls that have been chipped or broken by foreign objects, you will need to start planning for replacements.

Vibration

Vibrations in your processor may be caused by several problems. On models using springs or washers, check to see if they are broken. When you remove them from the processor unit, measure the spring or washer stack to see that the free length is still correct. If there is too much play or too little spring pressure, the roll will move excessively when feed is flowing through, causing a buzzing sound.

A bent shaft will vibrate all the time it is rotating, not just under a load. But a loose bearing may or may not vibrate. If you find that the bearing journals are worn or that the shaft is bent, you will likely need to replace the shaft or put a new roll in if it is too badly worn.

All Horning rolls are standard with replaceable shafts, but not all other brands have this feature.

The more you operate your kernel processor, the more familiar you will become with how it normally functions, and the more easily you will be able to tell when something doesn't seem right. If you are seeing any (or all) of the conditions we've just mentioned, it may be time to place another order.

If you think you may be getting close to needing a replacement, but you aren't sure if you can get just enough life from your rolls to finish a season, please contact us. We'll be glad to help you make a good decision. Contact your local Horning dealer.